On existing site characteristics or brownfields, many AEC projects are located. More time, money, and effort are used on projects that start with an inspection and documentation of the circumstances on the job site. Even if BIM services can automate new construction work, how can it be used for existing building documentation?

High-resolution 3D modeling of current built and natural settings are captured using the scan to BIM method and transformed into usable models. The time-consuming and customary process of current site documentation can be automated using laser scanning technology.

The scanners are positioned in various locations to collect the physical forms on-site. The 3D modeling created from the scans, known as “Point Clouds,” is converted into architectural drawings. How exactly does this procedure operate? Learn more about the specifics in this article!

Scan to BIM (Major details)

Different technologies are used today to modernize and provide better customer service. A cutting-edge method called SCAN to BIM Design Build harnesses the strength of 3D modeling and laser tracking technology with building information modeling. Construction experts may successfully plan projects from the final assembly stage through the use of laser scan to BIM technology, cutting the project duration by between 40% and 90%. A single reference file in a precise digital model is provided by the scan to BIM services design-build solution, giving customers various benefits like:

- Obtain Reliable Reference Data in Real Time

- Manage, Benchmark, Synchronize, and Organize Incoming Data

- Plan and improve the performance of new buildings

How does BIM relate to scan-to-BIM?

The need for BIM deployment and the production of BIM schematics for existing buildings is expanding within the AEC sector. Scan-to-BIM is rapidly turning into an essential step in the BIM process.

Before a designer even begins, reality capture of as-built drawings conditions can give the model the most important information when a project involves an existing structure or site, as it will in most cases.

Here is a straightforward summary: Scan-to-BIM uses laser scan data to digitally capture a physical place or site, which is then used to build, develop, and maintain a BIM model.

How Does Scan to BIM Process Work?

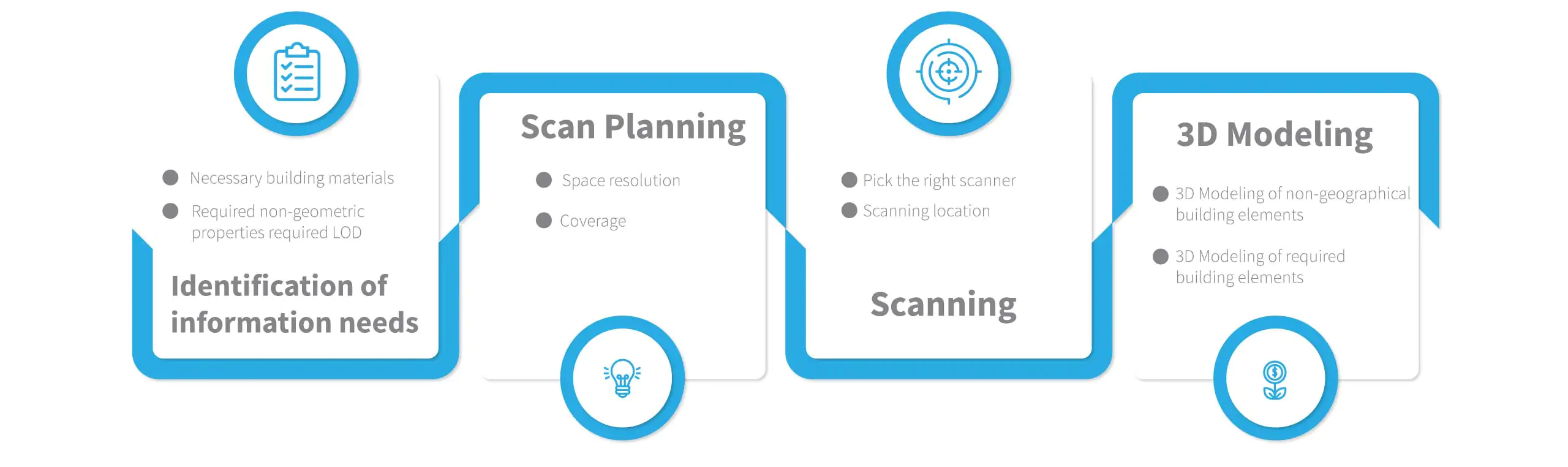

Four stages make up the complete Scan to BIM process:

Identification of information needs:

Before beginning the Scan to BIM process, it is crucial to identify all the information needs for the desired model and drawings. The amount of detail in your model must be determined because greater modeling accuracy increases the as-built BIM’s dependability for the intended application. However, the cost increases with the level of detail. Therefore, a trade-off between price and data density must be negotiated. We locate the following data at this stage:

- Necessary building materials

- Required non-geometric properties

- Required Level of Detail

Scan Planning:

Before capturing a 3D scan, settings are defined during scan planning. It is crucial since it is challenging to locate building design documentation that has already been completed. Therefore, optimizing the scanning parameters may be useful. It also entails determining all the properties required for scanning. The following list of parameter types includes:

- Space Resolution

- Coverage

Scanning:

A 3D laser scanner acquires data quickly and accurately and is used to perform scan-to-BIM operations. The tool has a quick-rotating, safe-for-the-eye laser. It is often set up on a tripod at the location, and as soon as the laser beam collides with a solid object, its location is recorded as points or coordinates. These points are mapped as a group, creating an extremely precise digital image. Once all the points have been collected, the scanner will colorize them to produce a point cloud scan or 3D representation of the location with numerous viewpoints.

3D modeling:

The final step in the scan to BIM process is to create a 3D BIM model of the existing building using the gathered Point Cloud Scan data.

What is the difference between a BIM model and a 3D CAD model?

In both types of models, the geometric details of a real-world structure are contained. To represent a building, 3D CAD drawings, on the other hand, uses “dumb” lines that are not organized into objects in the model.

For instance, when you look at a window drawing in a CAD model, you may be aware that you are looking at a window, but the CAD model sees the window as a collection of unrelated lines.

It helps to connect the asset’s geometrical information to its functional information. A window will be recognized as a window by the BIM model. However, lines are grouped into objects in BIM models.

Why is scanning to BIM important now?

The AEC sector has benefited from numerous intriguing and innovative technological advancements to increase its effectiveness. Scan to BIM is the most significant of the bunch. Many remodeling projects may see scan-to-BIM or point cloud-to-BIM modeling measures. Here, data is inferred using laser scanning technology, and useful 3D BIM models are built using these data.

- Scan to BIM facilitates enhanced cooperation, transparency, and communication.

- The BIM model created with the scan data allows for increased dependability and quality assurance.

- Lowers the price of construction

- Scan to BIM facilitates project modifications and promotes quicker decision-making

- Using BIM throughout the construction process improves the project’s sustainability

- The virtual development of the BIM model from scan data aids in preventing costly construction errors.

Lastly,

The experts at Getra Innovation are dedicated to offering ground-breaking, high-quality solutions in the field of “Design & Engineering,” Want to demo Getra Innovation own BIM design services? Get in touch with one of our experts here. We’ll help you out.