The computational simulation and design optimization of complex dynamic systems is a challenging task that requires the use of efficient numerical methods, efficient algorithms, and reliable computing platforms. This text provides a comprehensive treatment of various topics in this field and covers both classical and modern approaches to solving problems related to system simulation and optimization.

Numerical techniques are used to model fluid flows in CFD. For both new prototypes and existing systems, this approach aids quick system integration in order to optimize the configuration for cost and efficiency. Moving fluid, heat transmission, and chemical reactions are all part of the system.

What is a digital prototype?

A digital prototype is a representation of your concept in visual form.

Humans are extremely visual creatures. In reality, visual information is processed by more than half of the cortex, which is the brain’s surface. So, the most essential part about seeing a prototype is that you see it! That prototype comes to life when buyers can see it and comprehend all the product’s components.

Although prototyping is an important phase in the concept creation process, it may be perplexing for new entrepreneurs. It’s easy to see why: a prototype may be anything from a collection of sketches depicting various panels to a flawless pre-launch interface.

A virtual reality experience.

Virtual reality (VR) is a virtual experience that may be both comparable and dissimilar to the actual world. Virtual reality has a variety of uses, including entertainment (such as video games), education (such as medical or military training), and business (e.g., virtual meetings). Augmented reality and mixed reality, often known as extended reality or XR, are two more forms of VR-style technologies.

The next generation of simulation and optimization software is here!

Advance Stimulation

Getra Innovations is a company that specializes in sophisticated simulations such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) (CFD).

We think that simulating is essential for improving efficiency and dependability as well as continuing to innovate. Investing in simulation becomes critical if you want to avoid being disadvantaged by the market’s current competitiveness. Our FEA and CFD services aid in the evaluation of efficacy in all the sectors with which we work.

To give you a better perspective, here’s a quick primer on FEA and CAD:

FEA (Finite Element Analysis):

FEA essentially aids our designers in analyzing various alternative designs and weighing the benefits and drawbacks. This procedure aids us in selecting the optimal design for the product. FEA also allows us to test multiple modes of failure to see where the design may be improved. This saves time and effort, resulting in a rapid turnaround. Furthermore, if a requirement for design customization occurs, our designers can simply handle it by changing the measurements and modeling the impacts on the product. Designs are FEA-tested and given a final polish before being put into production.

We offer the most up-to-date tools and technology for analyzing product efficiency, which helps to reduce delays and drag the product finalization process.

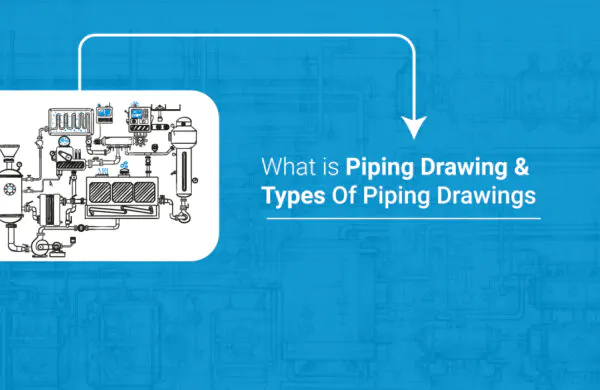

CFD stands for Computational Fluid Dynamics.

With the aid of CFD, the genuine product or physical structure is displayed. Numerical techniques are used to model fluid flows in CFD. For both new prototypes and existing systems, this approach aids quick system integration in order to optimize the configuration for cost and efficiency. Moving fluid, heat transmission, and chemical reactions are all part of the system.

Design Optimization:

Design optimization aids in the improvement of a product’s efficiency and performance. While our team of specialists optimizes a design, numerous external elements are considered to provide a trustworthy final result. If the design is unsustainable, there is a good chance it will fall short of the needed standards. We generate a number of alternatives, evaluate them based on a variety of criteria, and select the best design.

How does Getra Innovation help?

Getra Innovation provides design optimization solutions for implantable implants, renewable energy, turbomachinery, and other industrial goods using Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA)-based technologies.

Our unique automated mesh generators, 3D inverse and direct design tools, parameterized geometry models, target functions, and histopathology and thrombosis models are all part of our CFD/FEA-based design technology.

Monarch’s objective is to deliver cutting-edge CFD/FEA-based design optimization technologies, simulations, and modeling to assist our clients in developing high-quality, high-performance products in the quickest period feasible.

Conclusion:

Advanced Simulation and Design Optimization can help companies design products, processes, or services that are more profitable, safer, easier to use, and environmentally friendly. Getra Innovation offers these services in an affordable manner for any company looking to improve its product offerings. This is why Getra Innovation is the best company for you to choose if you are looking for an experienced team to help with your simulation and design optimization needs. Contact us today so we can work together on creating a strategy that will drive results.