Have you ever wondered how the complex pipework systems in factories, power plants, and oil rigs are designed and built? The answer lies in the intricate world of piping drawing. The engineers designing the piping system use these neat piping schematics as the diagrams to produce the pipework drawings that keep our modern world running. In this article, working on piping drawings is discussed closely including types of piping drawings and why they are vital.

What Is Piping?

At first glance, a piping drawing is a drawing for technical purposes that will show the layout, the configuration and the components of a pipework system. These drawings are a basic tool for all piping design engineers who employ them to plan, construct, and design pipelines for many industries like oil and gas, pharmaceutical, and chemicals.

Pipework drawing is a typical software drawing usually with the help of AutoCAD or Plant 3D which permits engineers to produce exact, correct, and simple-to-understand drawings. These schemes contain numerous symbols, symbols, and abbreviations representing numerous components, such as pipes, valves, pumps, and fittings.

Types of Piping Drawings

The piping drawing types have several categories, which are useful in the process of detailing the pipes, while others serve specific purposes.

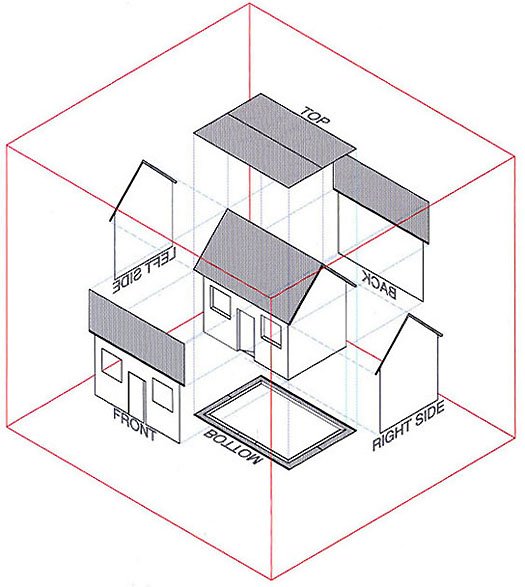

1. Piping Layout Drawings

The detailing of piping is done by the use of pipe layout drawings, also known as orthographic drawings; that represent the flow system in its overall layout and configuration. More often than not, these illustrations are drafted from above or next to them and have details about the size, shape, and location of pipes, valves, pumps, etc.

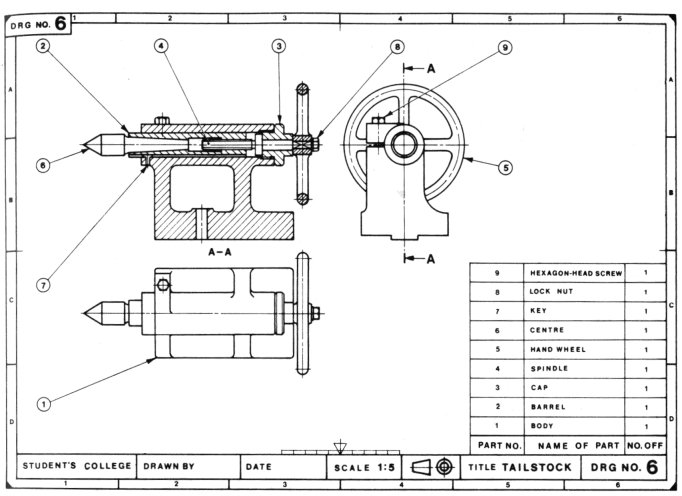

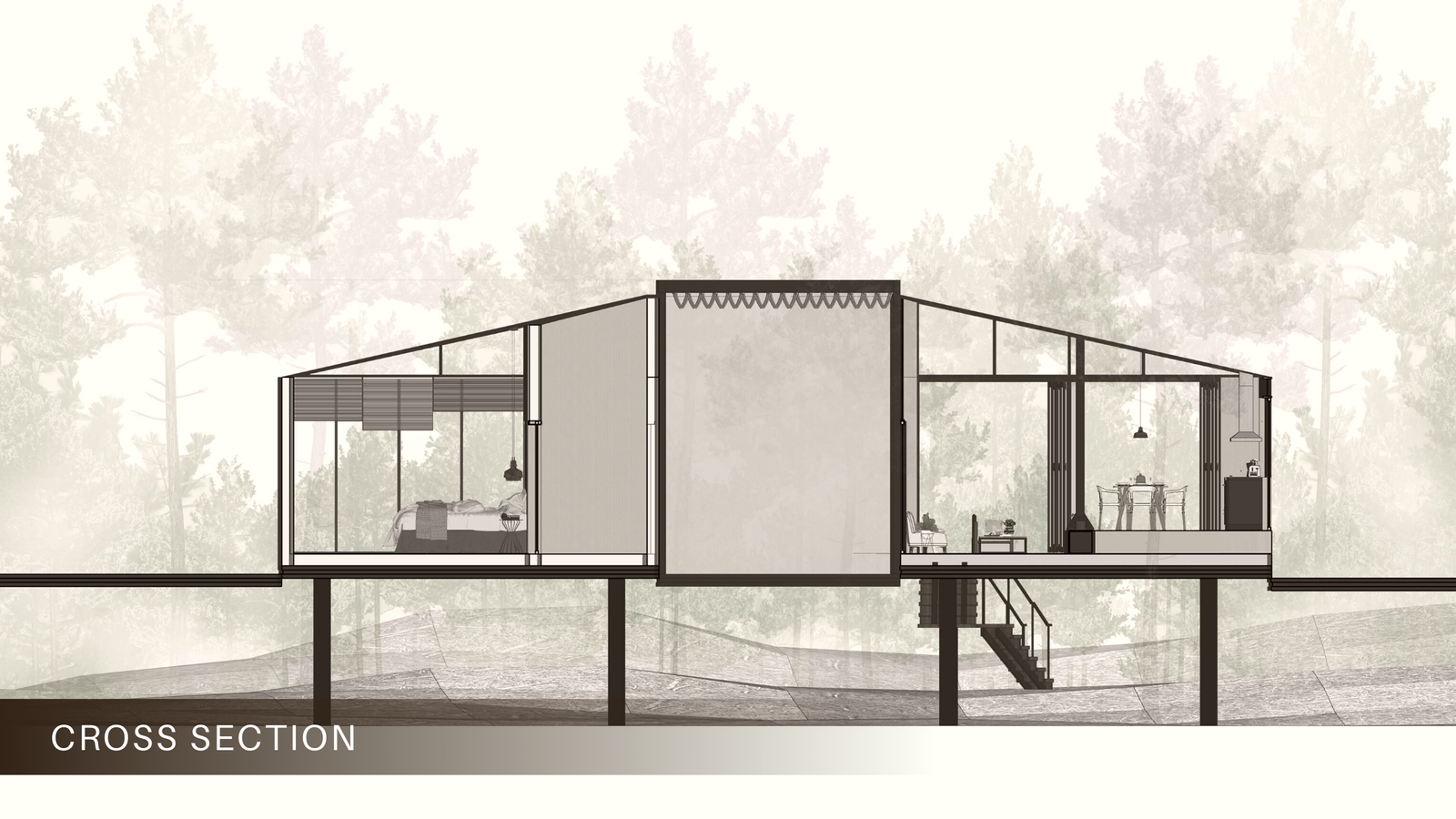

2. Isometric Piping Drawings

The Isometric Piping Drawings is a type of three-dimensional drawing in which the pipework system is depicted from various angles and directions. These drawings are impelled to supply a more detailed and authentic representation, emphasising the pipes, valves and other components’ shape, size and orientation.

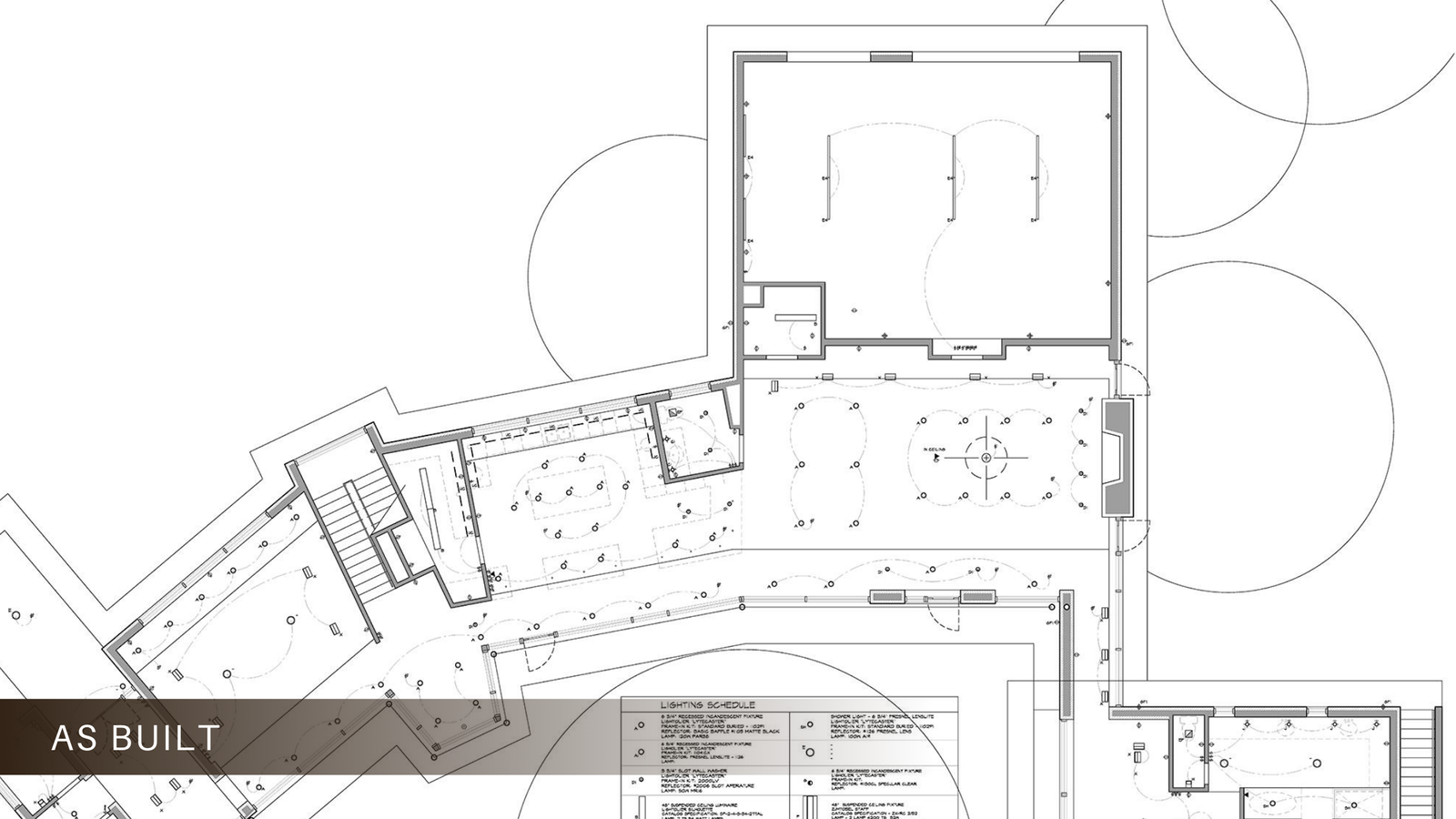

3. P&IDs (Piping and Instrumentation Diagrams)

The use of PIDs to demonstrate the connecting relationship between the piping and instrumentation systems in a process is one example. Such charts contain data about materials circulation, the position of sensors and control points, as well as interconnectivity of systems units.

4. Detail Piping Drawings

Detailed piping drawings illustrate a selected part or an area of the piping system and offer a closer look. Amongst these drawings, you will notice the size, shape, material and any particular features or circumstances of pipes, valves and other components.

Why Is It Important To Create Piping Drawings?

The details of a piping drawing are the blood and bone of the pipework design and construction process. They provide a precise and true media of the system, which helps Piping Design services engineers design and assemble the system with good quality and high speed.

While without piping drawings, the construction of an intricate pipework task is gradually made impossible. These drawings guarantee that all elements will be of proper size, and position, and will be correctly connected, hence reducing the risk of leaks, breakdowns and other possible failures.

Besides, precisely made drawings of piping are also used for maintenance, repair, and modification of the existing pipework system. The illustration of system-related drawings enables the maintenance personnel to make prompt and right decisions regarding the system’s flawless operation being intact and safe.

Conclusion

Piping drawings might look simple and obvious, but they are very important for the machinery of pipeline systems projects. The drawings allow for a clear and thorough representation of the system and ensure that all components are properly sized and situated where they should be and are connected to one another. Hence, leaks, failures, and other system issues are minimised or eliminated.

Either you are a piping engineer or maintenance technician, or you simply embrace the field of Mechanical Engineering Services; the interpretation of piping drawings is an integral component of that equation. Through having a grasp of what different types of piping drawings are used for you will be capable of moving within the wide world of pipework systems and understand how important they are to the present world.

You can get in touch with Getra Innovation if you need someone to oversee all project requirements and offer creative, dependable solutions that will exponentially boost your business’s potential for growth in the future. Getra Innovation creates specialised solutions to assist clients in re-engineering their manufacturing processes to maximise organisational efficiency and outcomes. With a staff of highly skilled individuals and cutting-edge infrastructure, Getra Innovation has a competitive advantage in the market.